Cleanroom Ready Hardware for a Higher Standard of Performance

Whether you’re building critical components or contamination-sensitive assemblies, UltraVac delivers expertly sealed, dependable hardware that supports your most demanding operations.

Engineered for Cleanroom Confidence

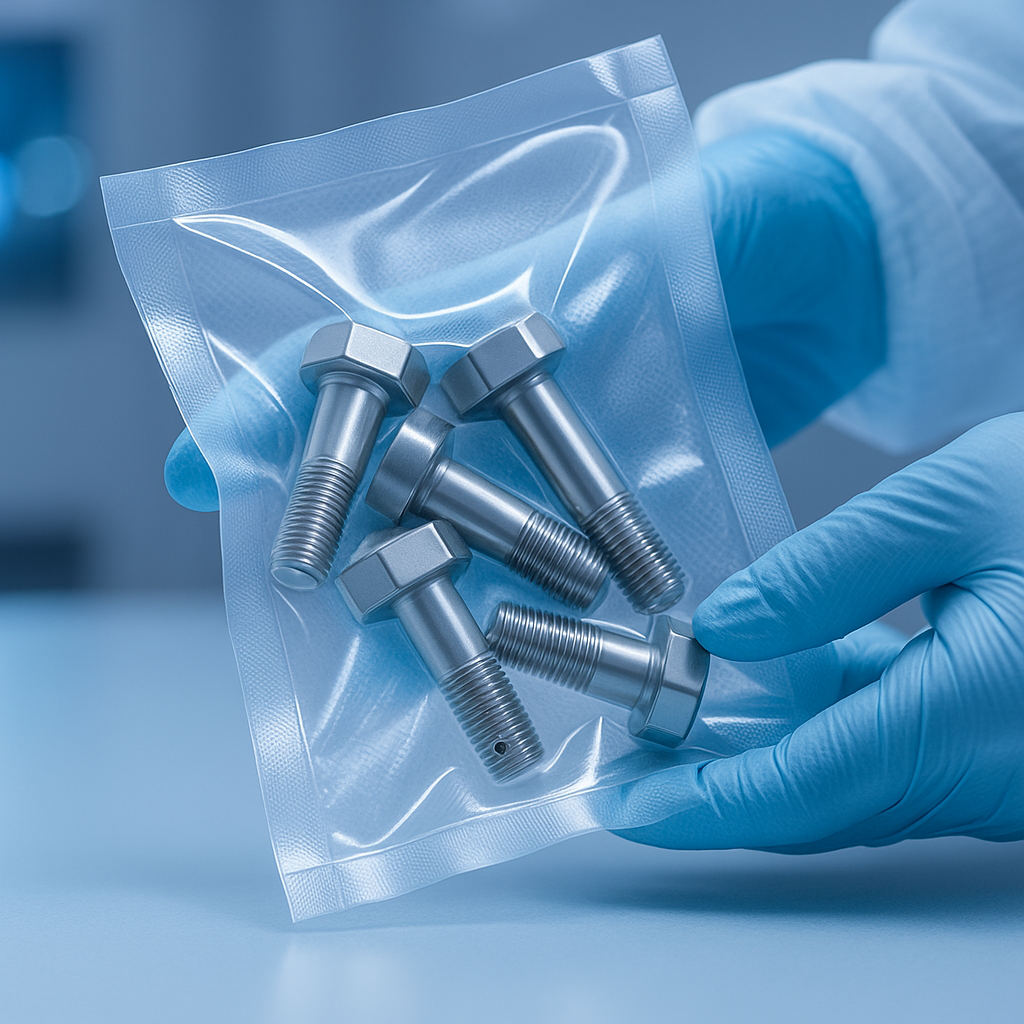

At UltraVac, we engineer cleanroom-ready hardware built to exceed the strictest contamination control standards. Our vacuum-sealed, precision-manufactured components support high-performance operations in industries where reliability and cleanliness are a non-negotiable.

Built for Cleanrooms. Trusted Around the World.

UltraVac Hardware are precision-cleaned, sealed, and ready to perform wherever contamination control matters most.

Cleanroom Ready Hardware, Delivered Through Trusted Distributors

UltraVac provides precision-cleaned, vacuum-sealed fasteners designed for contamination-sensitive environments. Our products are available exclusively through a global network of authorized distributors, each trained to support your cleanroom requirements with speed and reliability. Whether you need vented screws, custom kits, or support selecting the right part for your spec, UltraVac and our partners are here to help.

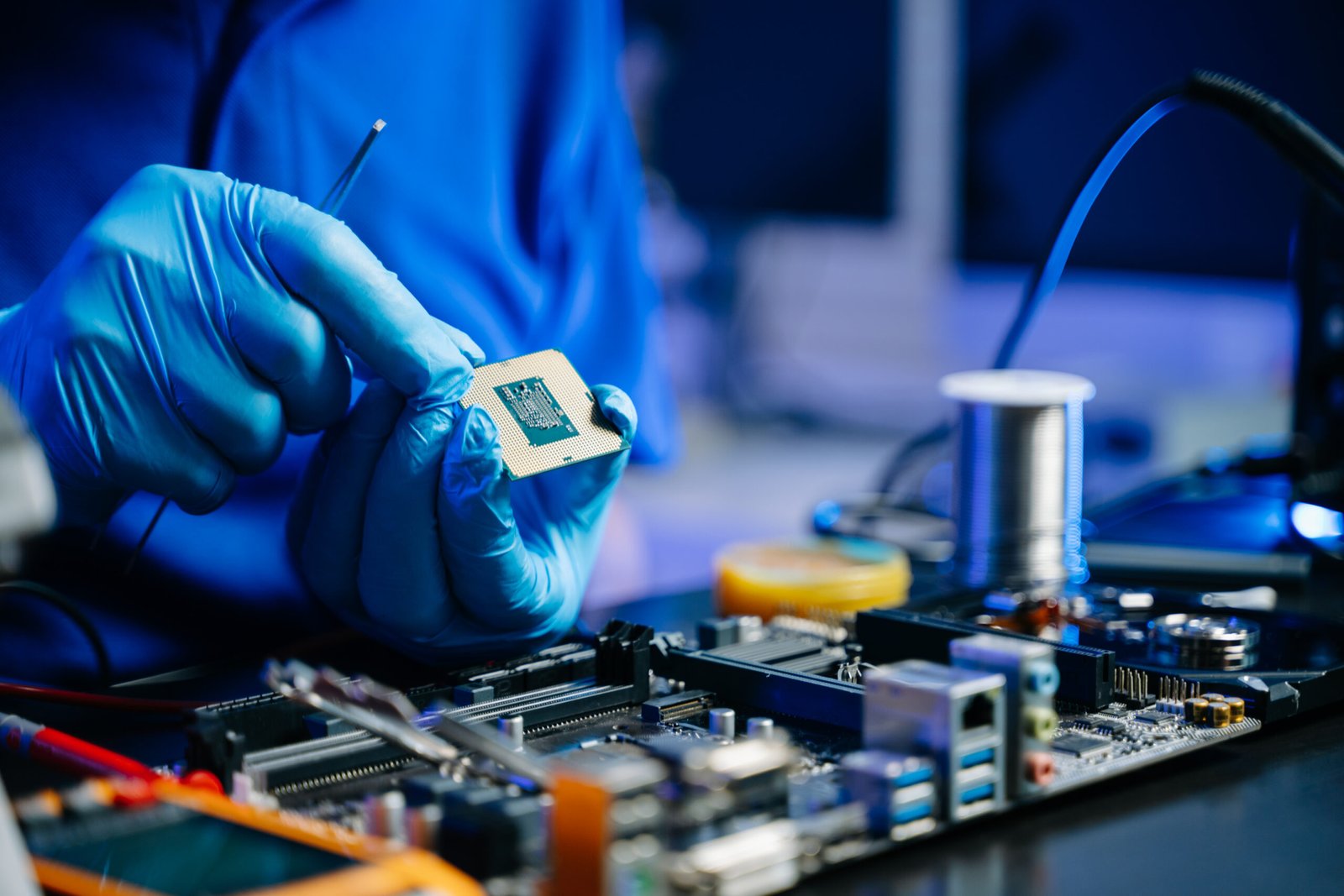

How Our Hardware Performs in the Field

Get in Touch with UltraVac Today

Have a question about our cleanroom-ready hardware, packaging process, or how UltraVac fits into your application? We’re here to help. While UltraVac products are available exclusively through authorized distributors, our team is happy to assist with general questions, product details, or technical guidance.

The Cleanroom Choice for Manufacturers Around the World

Join the growing number of OEMs, contract manufacturers, and cleanroom facilities who rely on UltraVac for hardware that meets the highest standards — cleaned, sealed, and delivered through our global distribution network.